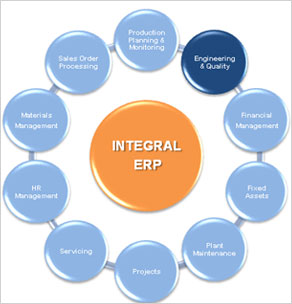

Engineering and Quality

Engineering in Integral-ERP is all about defining and controlling what goesinto the makin of the Product, that is, Bill of Material (BOM) and how to making it (Routing). The different catergorization of the items including the Products are defined here. The system has a APQP life cycle definition. Once a BOM is defined and frozen, any modifications are allowed only through Engineering change request and Engineering change notice. Integral ERP has a unique feature of defining a Design BOM, that is, Engineering Parts list and the manufacturing BOM gets generated automiatically on defining Routings in the system.

Quality Management in Integral-ERP is a comprehensive three stage Quality System that includes Incoming Material Quality, In-Process Quality and Final Stage Quality. Specifications of the items are captured as Masters and every lot is then inspected based on the inspection sheet printed by the system. Concepts of Sample Sizing are used wherever extended. Another unique feature is the Deviation Concept, which can be for a lot, a particular quantity or a particular period.

Our Clients