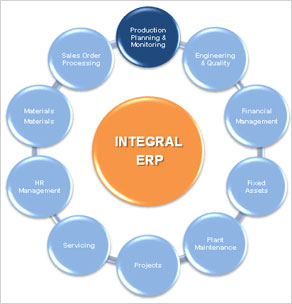

Production Planning and Monitoring

This module of Integral-ERP covers Master Production Schedule (MPS) prepared from the inputs from Sales Orders captured and forecast entered by the Sales team. MPS takes into account the finished stocks available and deliveries pending. The weekly MPS plans are broke down into daily Assembly Plans based on line capacity. The daily plan is then converted into shop orders against which actual production done is captured. Material Requirement Planning (MRP) in turn gives period wise plan for the components to be made inside the factory. The Shop Orders for factory made parts are also generated automatically. Production losses, if any, are captured against shop orders while executing them. The system then presents the Management with Production loss trend at the end of the period.

Our Clients